Tips for Pouring Concrete in the Winter

As we enter the winter season, one of the biggest questions we hear is, “Is it safe to pour concrete in winter?”

The short answer to this question is that yes, you can pour concrete during winter. However, there is more to it than a traditional pour, as there are certain precautions and considerations you will need to take to ensure your concrete job is done right.

Here are some tips to follow if you are considering pouring concrete in the winter.

Choosing the Right Concrete

Choosing the right concrete is vital if you are considering a winter pour. When choosing your concrete, you will want to look at the PSI or MPA and if the concrete is air-entrained. By selecting a stronger concrete, it will have better resistance for expansion. We suggest a minimum strength of 4,000 PSI. Using an air-entrained concrete will help relieve pressure if or when the water freezes.

Preparing the Site

Pouring concrete on frozen ground could shock the concrete and result in cracking, which is something you do not want to happen. Before you consider pouring your concrete, the site itself must be properly prepared.

● First, remove any ice, snow, or water from the area where you will be pouring the concrete.

● Use construction heaters to thaw or heat the ground.

● Pre-heat the water that will be mixed with the concrete to between 140° to 180° Fahrenheit.

● Have a moisture meter and/or thermometer readily available

Making the proper preparations for both your tools and the ground for your pour area is essential during the winter season.

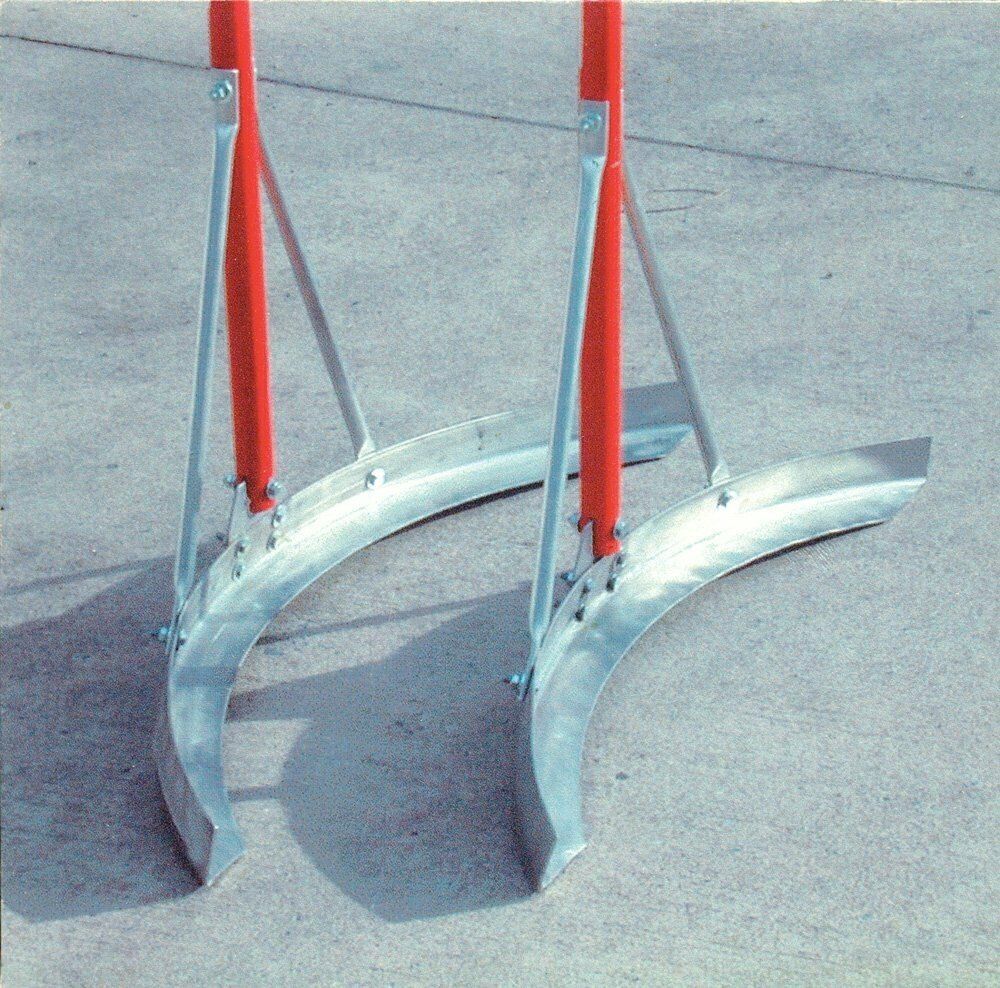

Appropriate Tool Preparation and Usage

Aside from preparing the ground, your tools are also important in making a winter pour successful. When preparing your tools, we suggest keeping them enclosed inside a warm area prior to the pour. If you do not have inside storage available, then we suggest having an additional heater onsite to warm the tools and any other equipment prior to use. If your tools or forms are cold, it will affect the strength and quality of the concrete.

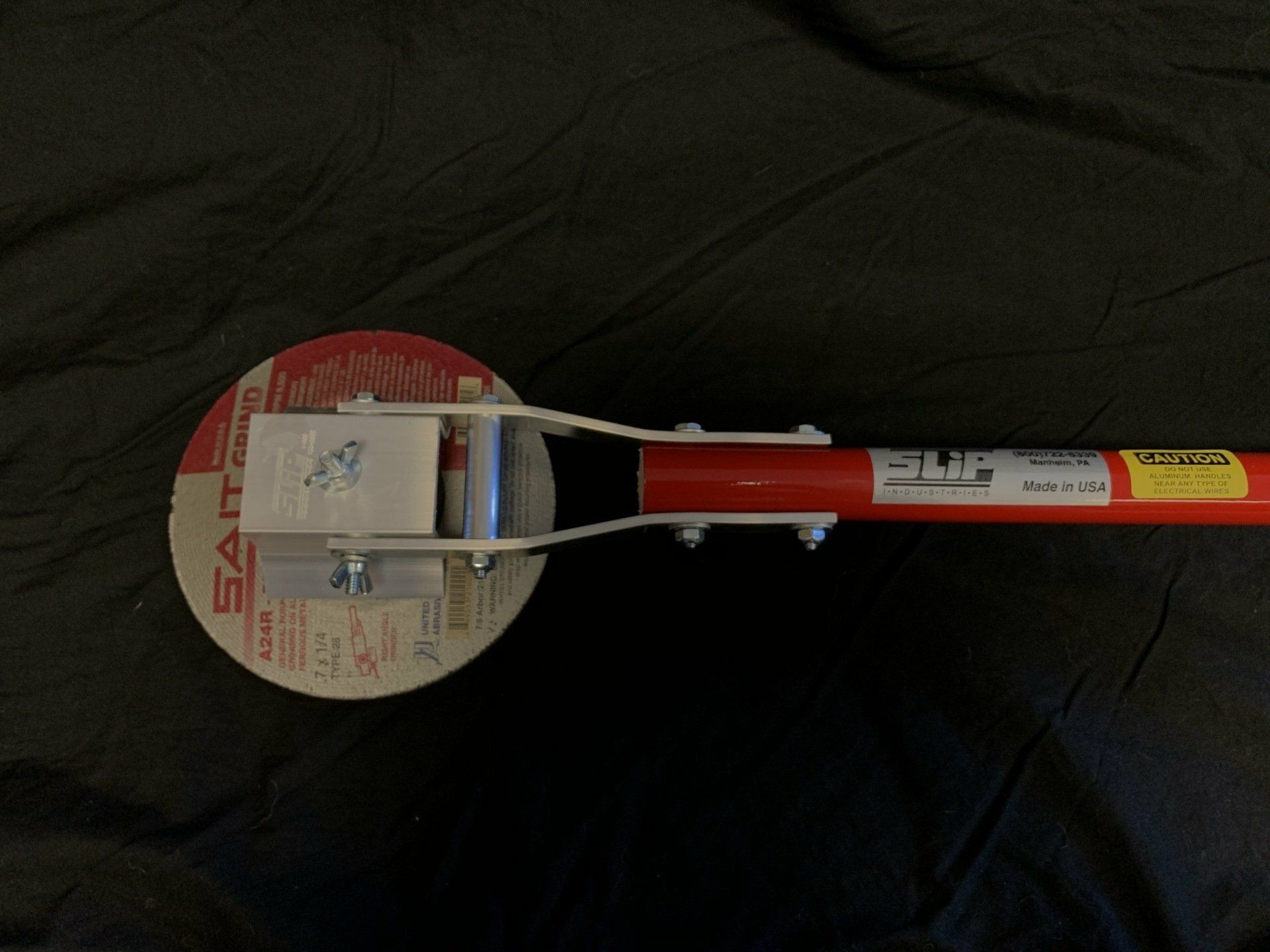

We also suggest having a moisture meter onsite during your pour, which will help you monitor the moisture levels in the concrete.

Preparing and using your concrete tools properly during a winter pour is crucial in helping the concrete cure the way it is supposed to.

During the Pour

When pouring the concrete, you must continuously monitor the temperature and make any adjustments accordingly. Here are some things to consider during the pour:

● As soon as the concrete is delivered, begin the pour. This allows the water and mix to keep their heated temperature.

● Use a moisture meter and/or infrared thermometer to keep checking the temperature of the concrete. Keep the concrete temperature at or above 50° Fahrenheit.

● Have blankets, lights, and heaters on site in case the temperature drops or you lose light due to the sun setting.

Monitoring the temperature is one of the most important things you can do during a winter pour to ensure the best quality of work.

After the Pour

Even when the pour is completed, the initial 24 hours after the pour are crucial for the concrete to set correctly.

In the winter season, do not seal the concrete until it has fully cured because it needs to sustain a minimum temperature of 50° Fahrenheit. We suggest trying to maintain this temperature reading for the first three to ten days post-pour for the concrete to keep its strength.

Your aiming point for the curing of the concrete is to be at 500 PSI because at that point it will limit any damage that could occur from the cold.

How We Can Help

At Slip Industries, we are a family owned business with over 30 years of experience in the concrete industry, providing the best American-made concrete tools to professionals nationwide.

No matter how big or small the job is, complex or simple, or even what time of year it is, we are here to serve you and assure that our tools will make it the best job you have ever done!

If you are starting a job or need tools for a job you are currently working on, contact us today at (717) 665-2139 to learn more about our products we create and how we can help you!