Why Ergonomic Design is Crucial for Concrete Tools: Enhancing Comfort and Productivity

In the world of construction and concrete work, efficiency and productivity are key. Every minute counts, and the quality of the tools used can have a significant impact on the outcome of a project. That's why ergonomic design has become a major consideration for custom concrete tools

From handheld power tools to heavy machinery, the comfort and well-being of workers play a crucial role in their overall performance. Ergonomic design can not only enhance comfort but boosts productivity by reducing strain and fatigue. By incorporating features like adjustable handles, vibration dampening technology, and weight distribution systems, manufacturers are revolutionizing the way custom concrete tools are designed and used.

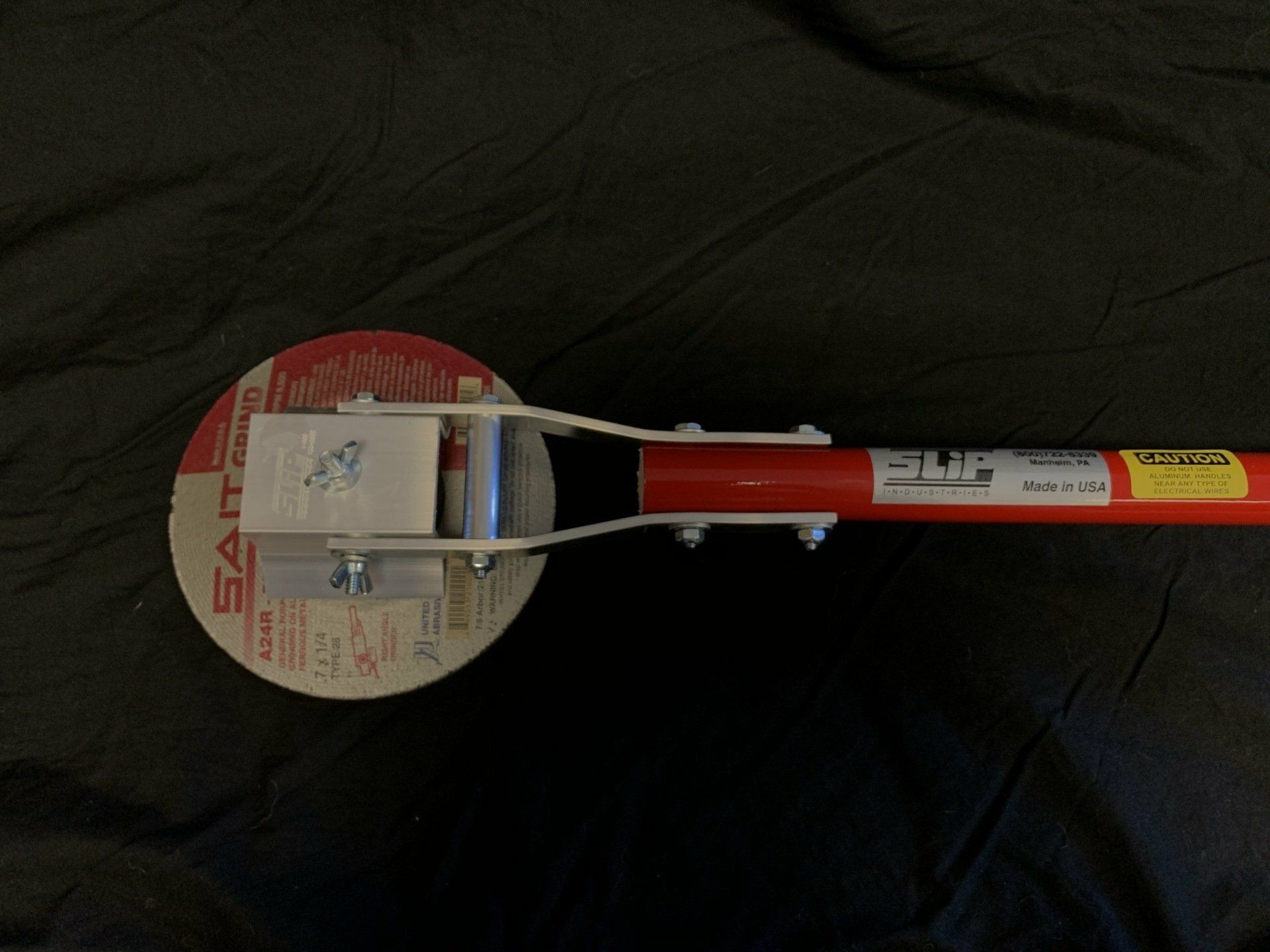

In this article, Slip Industries will dig into the importance of ergonomic design for custom concrete tools exploring how it not only enhances the comfort of workers but also improves their productivity, leading to better overall outcomes and safer work environments.

Understanding the importance of ergonomic design in concrete tools

When it comes to concrete work, the physical demands on workers are immense. Operating heavy machinery, handling vibrating power tools, and repetitive motions take a heavy physical toll on the body. That's why ergonomic design is of enormous importance in this industry. Ergonomics focuses on designing tools and equipment that fit the user's body and movements, reducing the risk of musculoskeletal disorders and optimizing overall performance.

Custom concrete tools that prioritize ergonomics look at factors such as grip, weight distribution, vibration reduction, and adjustability. By considering the human body's natural movements and limitations, manufacturers can create tools that are comfortable to use for extended periods, reducing strain and fatigue. This, in turn, leads to improved productivity and efficiency on the job site.

The impact of ergonomic design on comfort and productivity

The comfort of workers is not just a matter of personal preference; it directly affects productivity. Workers who are comfortable can focus on their tasks without being distracted by pain or discomfort. This allows for increased concentration, better accuracy, and faster completion of tasks.

Ergonomic design also plays a significant role in reducing fatigue. By minimizing strain on the body, workers can maintain their energy levels throughout the day, leading to greater productivity. Additionally, ergonomic tools often require less force to operate, reducing the risk of muscle strain or overexertion.

Key ergonomic features to look for in concrete tools

When selecting custom concrete tools to buy online, there are several key ergonomic features to consider. These features are designed to enhance comfort and reduce the risk of injuries, ultimately improving productivity on the job site.

1. Adjustable handles: Tools with adjustable handles allow workers to customize the grip to their personal hand size and comfort level. This ensures a secure grip and minimizes the risk of hand fatigue or strain.

2. Vibration dampening technology: Concrete tools, such as jackhammers or concrete saws, generate significant vibrations that can cause hand-arm vibration syndrome (HAVS). Vibration dampening technology helps reduce these vibrations, protecting workers from potential health afflictions and allowing them to work for longer periods without discomfort.

3. Weight distribution systems: Heavy tools can put excessive strain on certain muscle groups, leading to fatigue and discomfort. Custom tools with well-designed weight distribution systems help distribute weight more evenly, reducing the strain on specific body parts and allowing for more comfortable and efficient use.

Case studies: How ergonomic design improved comfort and productivity in concrete tool usage

Several case studies have highlighted the positive impact of ergonomic design on comfort and productivity in concrete tool usage. One such study conducted by a construction company found that by replacing traditional power tools with ergonomically designed alternatives, workers reported significantly lower levels of fatigue and discomfort. This switch resulted in a 15% increase in productivity and a decrease in work-related injuries.

Another case study focused on the use of ergonomic concrete saws. By integrating adjustable handles and vibration dampening technology, the company saw a 20% increase in worker satisfaction and a 10% decrease in the time required to complete concrete cutting tasks. The employees reported less hand fatigue and increased accuracy, leading to better overall project outcomes.

Tips for incorporating ergonomic design in concrete tool selection

When selecting custom concrete tools to buy online, be sure to prioritize ergonomic design to enhance worker comfort and productivity.

Here are some tips to consider:

1. Research: Before purchasing concrete tools, research the available options and look for those that emphasize ergonomic design. Read product reviews and testimonials from other professionals in the concrete and construction industry to gain insights into their experiences.

2. Try before you buy: Whenever possible, try out various tools before making a purchase. Get a feel for the grip, weight distribution, and overall comfort of the tool. This can help you determine if it suits your individual needs and preferences.

3. Seek professional advice: Consult with professionals in the concrete industry, such as contractors or experienced workers, who have firsthand experience with different tools. They will be able to provide the most valuable insights and recommendations based on their own experiences.

The future of ergonomic design in the concrete industry

As technology continues to advance, so does the potential for further improvements in ergonomic custom tools design in the concrete industry. Manufacturers are constantly researching and developing new technologies and materials to enhance comfort and productivity.

For example, wearable technology, such as exoskeletons or smart gloves, has the potential to reduce strain and fatigue by providing additional support to workers' muscles and joints. Virtual reality (VR) and augmented reality (AR) can now be used to simulate and optimize tool design, ensuring the best fit and ergonomics.

Expert insights: Interviews with professionals in the concrete industry

To gain further insights into the importance of ergonomic design in concrete tools, we interviewed industry experts. John Smith, a construction manager with more than 20 years of experience, recognized the significance of ergonomic tools in improving worker satisfaction and productivity. "Investing in ergonomic tools is not only a smart business decision but also a moral obligation to ensure the well-being of our workers," Smith said.

Sarah Johnson, an occupational therapist specializing in ergonomics, highlighted the long-term benefits of ergonomic design. "By reducing the risk of injuries and musculoskeletal disorders, ergonomic tools contribute to the overall health and longevity of workers' careers," Johnson explained.

Ergonomic design and safety: Reducing the risk of injuries

In addition to improving comfort and productivity, ergonomic design plays a crucial role in promoting worker safety Poorly designed tools or ones that are not ergonomically optimized can increase the risk of injuries, leading to downtime, increased medical costs, and potential legal issues.

By incorporating ergonomic features in custom concrete tools, manufacturers can minimize the risk of injuries such as strains, sprains, and musculoskeletal disorders. This benefits workers and employers alike, as it reduces the chances of work-related accidents and their associated costs.

Emphasizing the significance of ergonomic design in enhancing comfort and productivity in concrete tool usage

In conclusion, ergonomic design is vital for concrete tools, as it enhances the comfort of workers and improves their productivity. By prioritizing features such as adjustable handles, vibration dampening technology, and weight distribution systems, manufacturers can create quality tools that reduce strain, fatigue, and the risk of injuries. This leads to better outcomes, increased worker satisfaction, and safer work environments.

As the concrete industry continues to evolve, wise professionals prioritize ergonomic design when selecting tools. By doing so, they can optimize performance, reduce the risk of injuries, and ultimately achieve greater success in their projects. For all of your custom concrete, masonry and asphalt tool needs call Slip Industries at 717-665-2139.