Tips for Handling a Lute

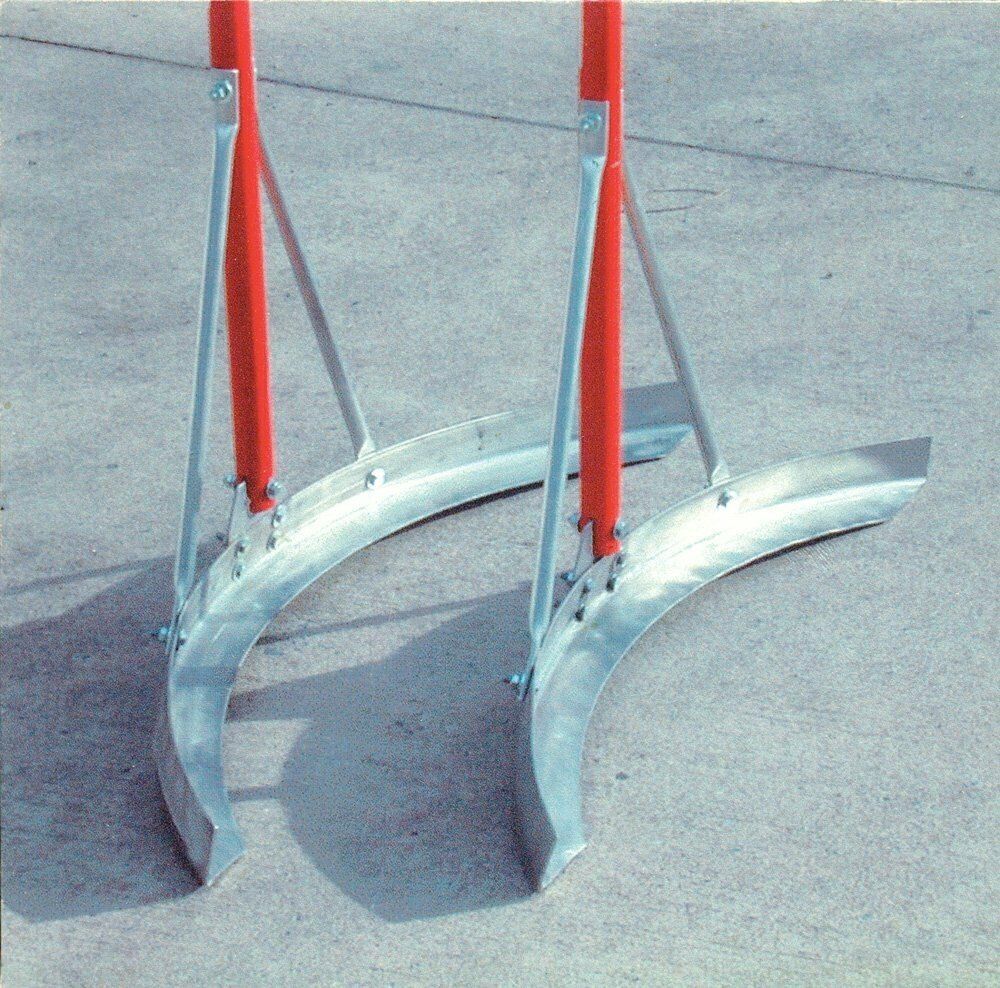

The lute is typically made of wood or aluminum and has a blade that has a straight edge on one side and a serrated edge on the other. The serrated edge is used to roughen a surface while the straight edge is used for smoothing. Lutes can come in a variety of sizes and lengths. The most common lutes have a 30” blade and has a handle that is 6 feet long.

The person that is using the lute has a very important role on a paving crew. Spotting areas in the material that are uneven is crucial to having a clean finish when working with asphalt. The crew member that is the “lute man” will use the lute to smooth out the material. They will use the lute as a leveling tool. The lute man should be keeping an eye on the material looking for high spots and low spots. High spots need to be smoothed out using the lute to keep the surface even. If there is a low spot, the lute man needs to recognize this as well because it can be an area where water will gather in a puddle. This would need to be filled in and smoothed with the lute as well.

The lute man will have one hand lower on the lute and the other at the top of the handle. They can then use their forearm as a guide to keep the lute level. This will minimize the chance of the angle they are holding the lute from varying. The lute man will work the material as it is shoveled on to the work area and they are tasked with pushing and pulling the hot asphalt mix to fill in gaps or smoothing out bumps. Knowing how much pressure to apply, where and how to efficiently move material and getting a feel for keeping a surface even takes a lot of time, patience and practice.

Keeping your tools in working order is always important. This is no different whether you have a power tool or a hand tool like a lute. In day to day work, excess asphalt will build up on the blade of a lute. When pulling asphalt, it will accumulate on the inside of the lute blade and then on the outside when pushing it. It is a common practice to spray the blade of the lute with a lubricating agent that will aid in reducing the amount of asphalt that builds up on a blade. The asphalt will slide off the blade more easily, which also helps in guaranteeing you keep your work area even. Slip Industries also sells replacement parts for the lutes they manufacture.

Slip Industries is proud be a company that has American made tools that you can buy online.

Whether you work with asphalt, concrete or general masonry, we’re a company that you can trust to deliver quality products, every time.

Contact us today to ask us any questions you have.